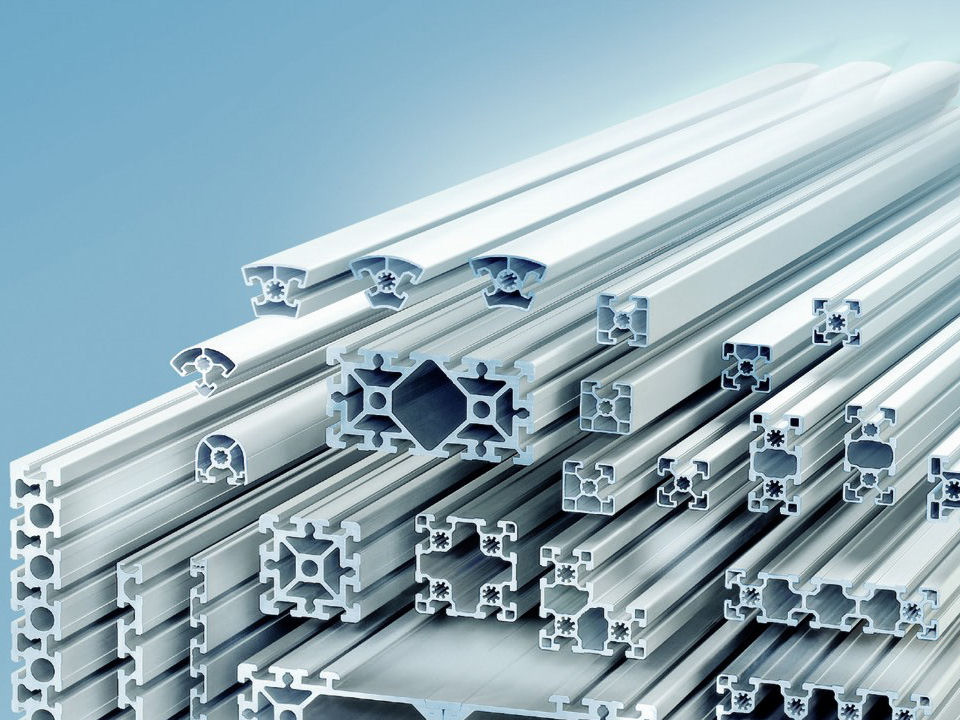

The use of modular aluminium extrusions is growing with each day’s demand for various aluminum products. Aluminum is used in creating produects for various things like electronic and automotive. Known for its wonderful qualities such as durability, reliability, longevity, and its strong and strengthening properties along with its most acknowledged lighter weight. It is much appreciated by people and industries all over, and these very qualities of aluminum are enhanced when it goes into the process of aluminum extrusion. These aluminum extrusion profiles are then used for various purposes in everyday markets and are valued accordingly. Be it aerospace, engineering, or automotive industries, they all value aluminum extrusion profiles.

Aluminum is very much resistant to corrosion, along with its strengthening and longevity properties. The extrusion process allows the aluminum to be designed in the desired shapes and sizes, which can be further used by firms and industries according to their demands. Even if the complex and tough shapes are demanded, the extrusion process makes it all easy and possible. Engineers, designers, and architecture experts are in need of customized aluminium profiles, now and then to meet their needs and create new outputs more effectively.

Also, the aluminum extrusion process is highly eco-friendly, since it lets people use aluminum again by recycling it through the extrusion process. This lessens the damage caused to the environment and also improves overall productivity while taking care of environmental concerns. Along with the environmentally friendly impact of this manufacturing process, the extrusion of aluminum is also very cost-efficient, which makes a very low cost of production per unit of the given material. This can be beneficial for businesses that are growing, to invest their money and resources in other important aspects, and gain profits from minimal investments in materials like aluminum extrusion profiles.

In almost all types of industries and organizations, aluminum extrusion profiles are being used, since the extrusion process makes the aluminum more useful, reliable, and of value. Other than that, the metal remains a mere object of no importance, unless it is extruded and changed or modified in certain shapes and sizes to be a product of further economic value, and consumer usage. Moreover, interestingly the maintenance cost of the aluminum extrusion process is very minimal, which makes the entire thing cost-efficient for the producers and manufacturers, especially those who need the extruded aluminum profiles regularly. With more and more businesses becoming aware of the wonderful process of extrusion that makes aluminum worth the correct value, they are demanding each day for extrusion aluminum profiles. And this way, the metal markets, and overall economy are gaining a significant pace for growth and development altogether.

What Is The Process Of Aluminum Extrusion

The extrusion of aluminum is a manufacturing process, which helps in changing the shapes and sizes of aluminum, in the desired result. After a heating and pressuring force, the aluminum is extracted to be ready for any specific shape that is needed at the moment. This process of extrusion is gaining ground in the industrial sphere, since it helps all other major and minor industries like aerospace, engineering, automotive, telephonic, solar, and others, to have components and parts made easily with extruded aluminum, so that they can give more value and an added quality to their final products.

This extrusion process usually takes place by starting to select the aluminum alloy billets, which are just like logs of aluminum made in cylindrical shapes. These are then taken to the heating areas where there is a temperature ranging between 750°C to 500°C, depending on the aluminum billet. After the heating process is completed, the aluminum billets are then cut in certain specific lengths, before taking them for the final extrusion process.

Then those heated and cut pieces are finally put into the extrusion dyes, where a heavy force of about 1000 tons to 15000 tons, is released. This force pushes the aluminum billet for extrusion and the aluminum then flows through another end of the dye in a continuous motion. The aluminum billet is then put in different shapes and sizes as demanded, and the extra coatings, powdering, etc. are then done. The final shapings and moldings are done once the aluminum cools down a bit through air and water. Also what is important to remember, is that throughout the aluminum extrusion process, the standard quality control measures are taken care of, so that the final product remains errorless.

The extrusion process is therefore highly important in today’s world, because of the versatility which it has in shaping aluminum in any and every desired shape and size. The final product, when used further by various industries for other processes, becomes highly useful, and effective for further economic profits and subsequent successes of the firms.

Where Are Aluminum Extrusion Profiles Required

The aluminum extrusion profiles are well known for their versatility, longevity, and strength along with their lightweight properties. This makes more and more industries use extruded aluminum more profoundly and abundantly.

- In the construction industry, extruded aluminum plays an important role, since it can be very useful in creating door frames, windows, and similar structures. The extruded aluminum has a lot of strength, durability, and anti-corrosion properties which makes it an important component in the construction industry.

- When it comes to transportation, the aluminum extrusion profiles, are very beneficial in making engines, and other important components of the vehicles. Moreover, the longevity and durability of the extruded aluminum profiles give the vehicle, too, a greater lifespan.

- In the aerospace industry, the weight has to be quite precise. There, the aluminum extrusion profiles are very advantageous, since these can be used to make lightweight seats, structures, and other vital components of the spacecraft itself.

- The extruded aluminum profiles are also a great choice if one wants to have lightweight everyday furniture, and that too with a good life and greater durability.

- Many parts of the electronic appliances such as refrigerators, and others, are made of extruded aluminum metals, which helps the creative team too, to develop a strong and reliable appliance for better usage with optimal performance.

- Conveyor belts, robotic systems, machinery, and their vital components, all use heavy amounts of extruded aluminum profiles. Even the solar panel frames, medical carts, wheelchairs, bicycles, and almost all items that we use in our everyday lives, use extruded aluminum profiles for better quality and light weighted-ness.

Therefore, the adaptability and the flexible and reliable nature of these aluminum extrusions, make them appealing and much needed. All the industries are interdependent, and in this sphere, the extrusion industries mount the rock since these prepare the base of the goods that will be further prepared and produced for better value in the larger global economy.

Conclusion

Hence, with the global economy, market dynamics, and technological advancements, all the sectors like automation, engineering, solar, electronics, and others, are increasingly using the metal extrusion processes, to ease the overall productivity and be able to achieve profitable success.