Speed and accuracy are foremost when assembling outfits. The capacity to deliver equipment rapidly while keeping up with immaculate exactness gives gear makers a valuable chance to create parts for many applications. One stuff fabricating strategy that can assist with accelerating creation, further developing accuracy, and lessening costs is hobbing. To support your stuff fabricating effectiveness and accuracy so you can take on new business however, don’t have the capital or transfer speed to put resources into gear hob cutters or recruit new representatives, re-appropriate your parts to a believed accomplice who can assist with expanding your ability to take on new ventures.

Advanced gear technology

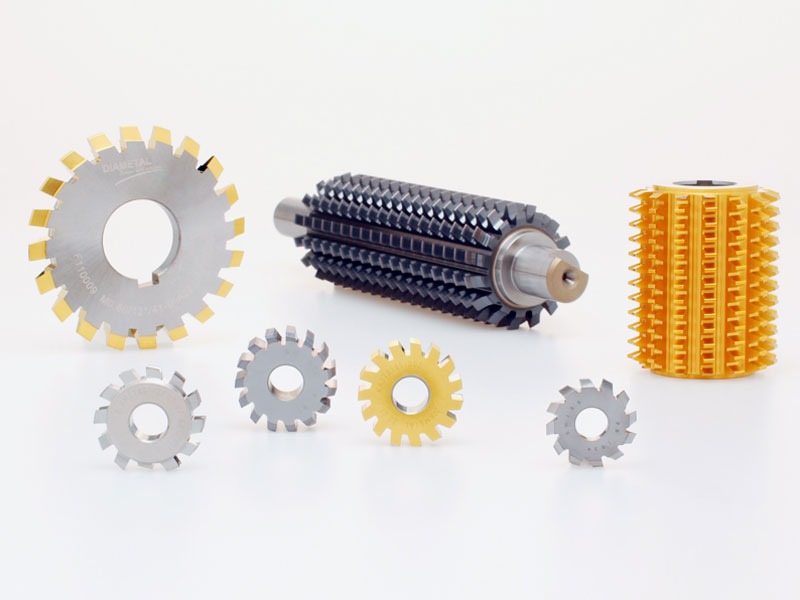

In recent years, notable technological advancements have been made in the gear hob manufacturing industry. Manufacturers make significant R&D investments to create effective and high-quality hobs. The design and production process has been completely transformed using sophisticated CAD and CAM software. CNC machines, which can produce complex geometries with high accuracy and precision, are used by modern hob manufacturers.

Speed

The speed and feed of the stuff hobbing machine decide the pace of material evacuation and the surface completion of the stuff teeth. They additionally impact the temperature and wear of the hob and the stuff. To amplify the effectiveness of the stuff hobbing machine, you want to pick the ideal speed and feed esteems that balance the efficiency and nature of the cycle. You can use exact diagrams or conditions to appraise your machine and the material’s speed and feed values.

What should customers expects?

The most crucial lesson is remembering that suitable blanks are the foundation of good gear. The quality of the hobbing process is directly impacted by the quality of the gear blank that needs to be hobbed. Maintaining the diameter where the gear teeth will be cut concentric with the axis of rotation is one of the process’s most crucial elements. This usually means that the outside diameter of both internal and external gears is maintained concentric with the bore or another designated datum. Lastly, the mounting face is an additional crucial component.

Quality control

It is essential in gear hob fabricating. The stuff hob should meet the necessary determinations to guarantee that it works accurately and doesn’t harm the hardware. Gear hob manufacturers in India utilize various testing techniques, including gear roll and profile testing, to guarantee that the hob is excellent. A few makers likewise utilize non-horrendous testing techniques, such as ultrasonic and attractive molecule testing, to recognize any deformities in the hob.

Accuracy

The dimensional and geometric accuracy of the gear teeth, as well as the noise and vibration of the operation, are all influenced by the rigidity and accuracy of the gear hobbing machine. You should also use appropriate alignment and calibration techniques to reduce machine errors and deviations.

Enhance precision

It has put resources into gear hobbing so we can rapidly create leaves behind steady and precise tooth math. Utilizing a hobber permits us to control gear tooth aspects and profiles intently. Customization is fundamental in such cases. Makers work intimately with their clients to plan and create hobs that meet their necessities. Tweaked hobs are often more costly than standard hobs because of the extra cost of planning and assembly.